Precision Automation to Streamline Workflows

Ultra-precision of

±0.05 mm

Industrial robotic arm Telos complements human capabilities to ensure flawless execution of tasks requiring exceptional detail with an accuracy of ±0.05 mm.

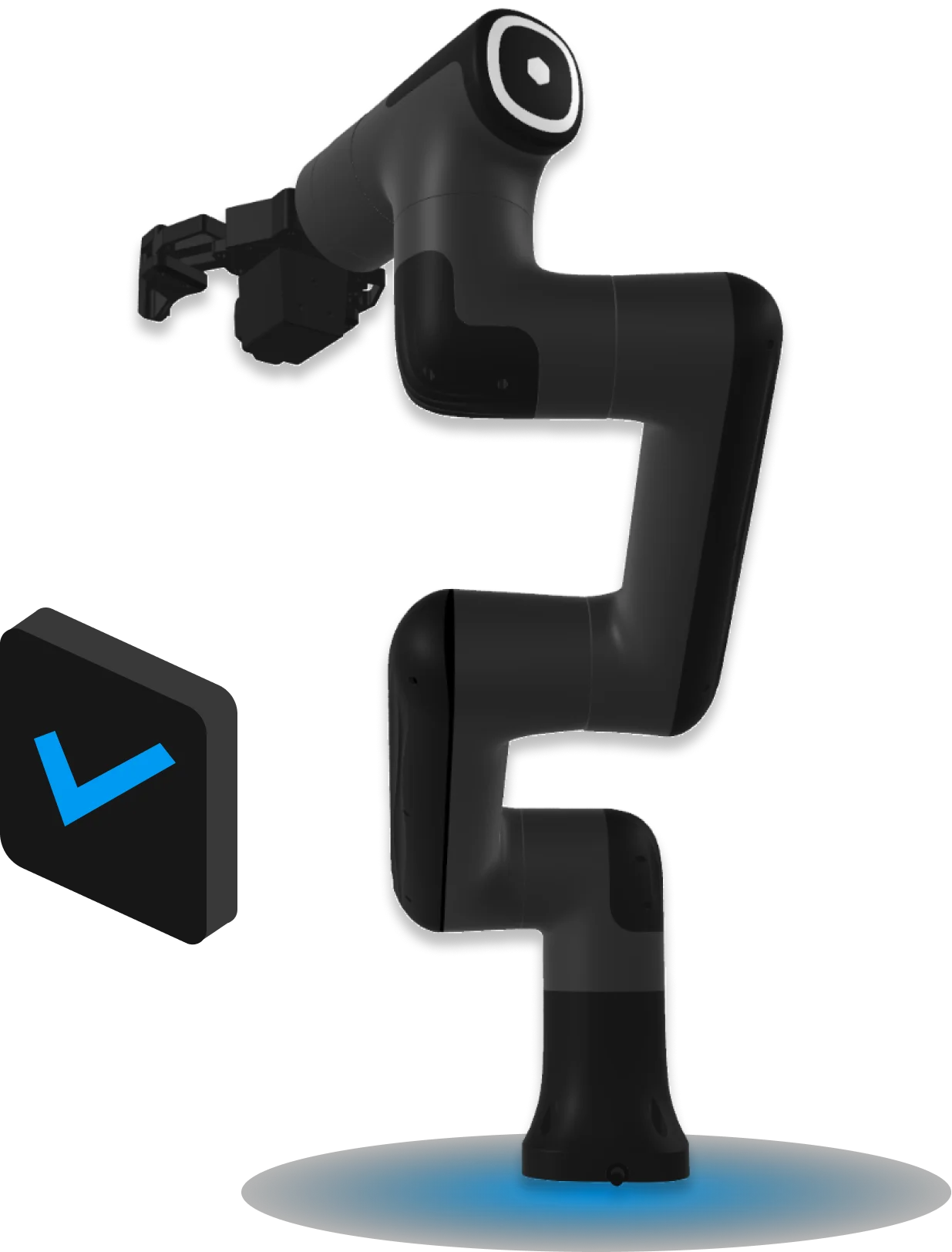

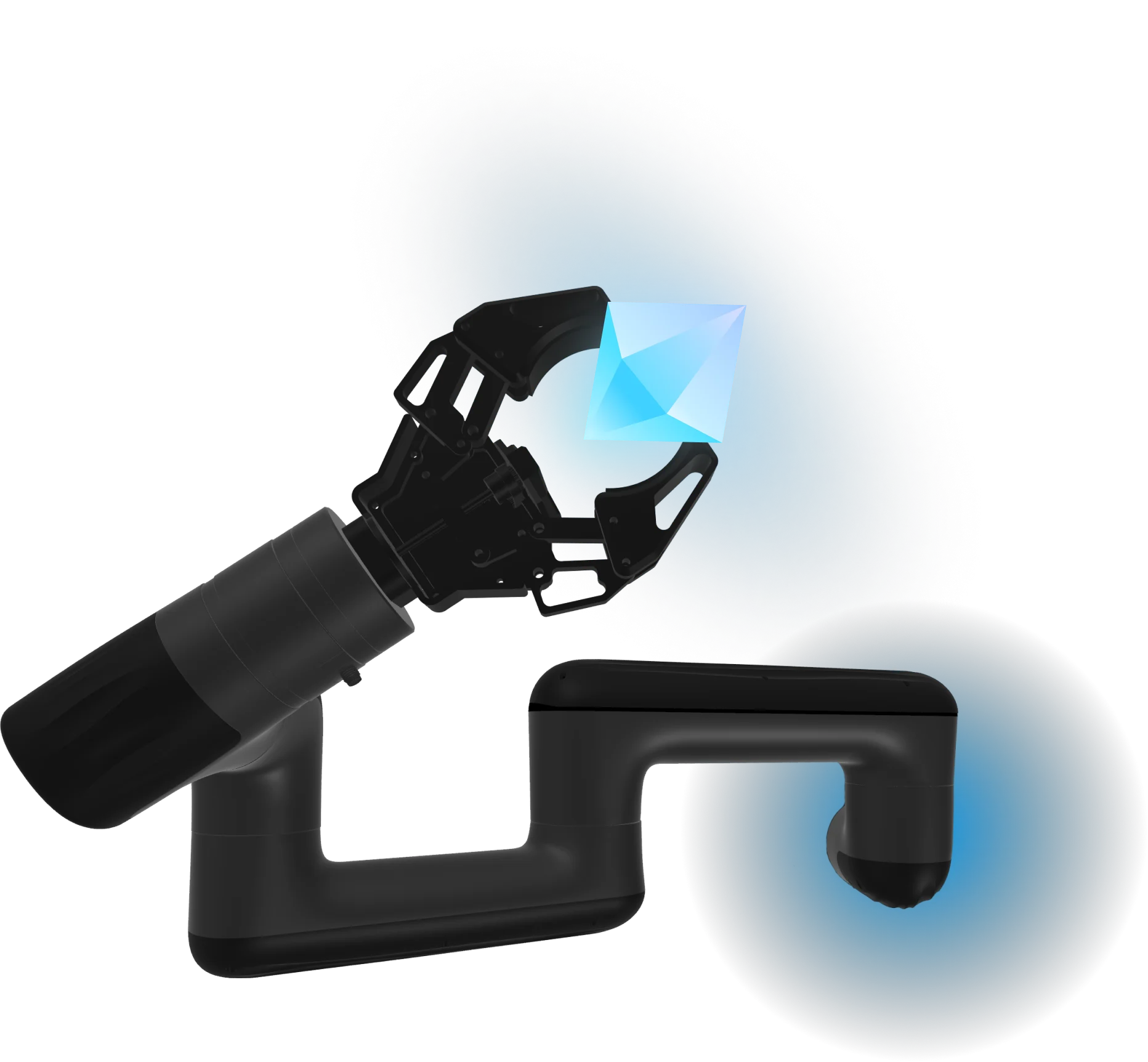

Multifunctional

Design

Adaptable to various needs, Telos’ modular structure allows for swift customization with different tools, making it perfect for a wide range of applications.

Payload Capacity

Boasting a payload capacity of up to 5 kg, Telos is robust enough to handle substantial loads yet gentle enough to perform tasks requiring the utmost care.

Technical Specs:

| Weight | 14 Kg |

|---|---|

| Maximum Payload | 5 Kg |

| Working Radius | 850 mm |

| Max Speed of TCP | 2 m/s |

| Range of Motion | J1: ±360°, J2: ±180°, J3: ±160°, J4 to J6: ±360° |

| Maximum Joint Speed | J1 to J6: 100° /s |

| Repeatability | ± 0.05 mm |

| Noise Level | 70 dB (A) |

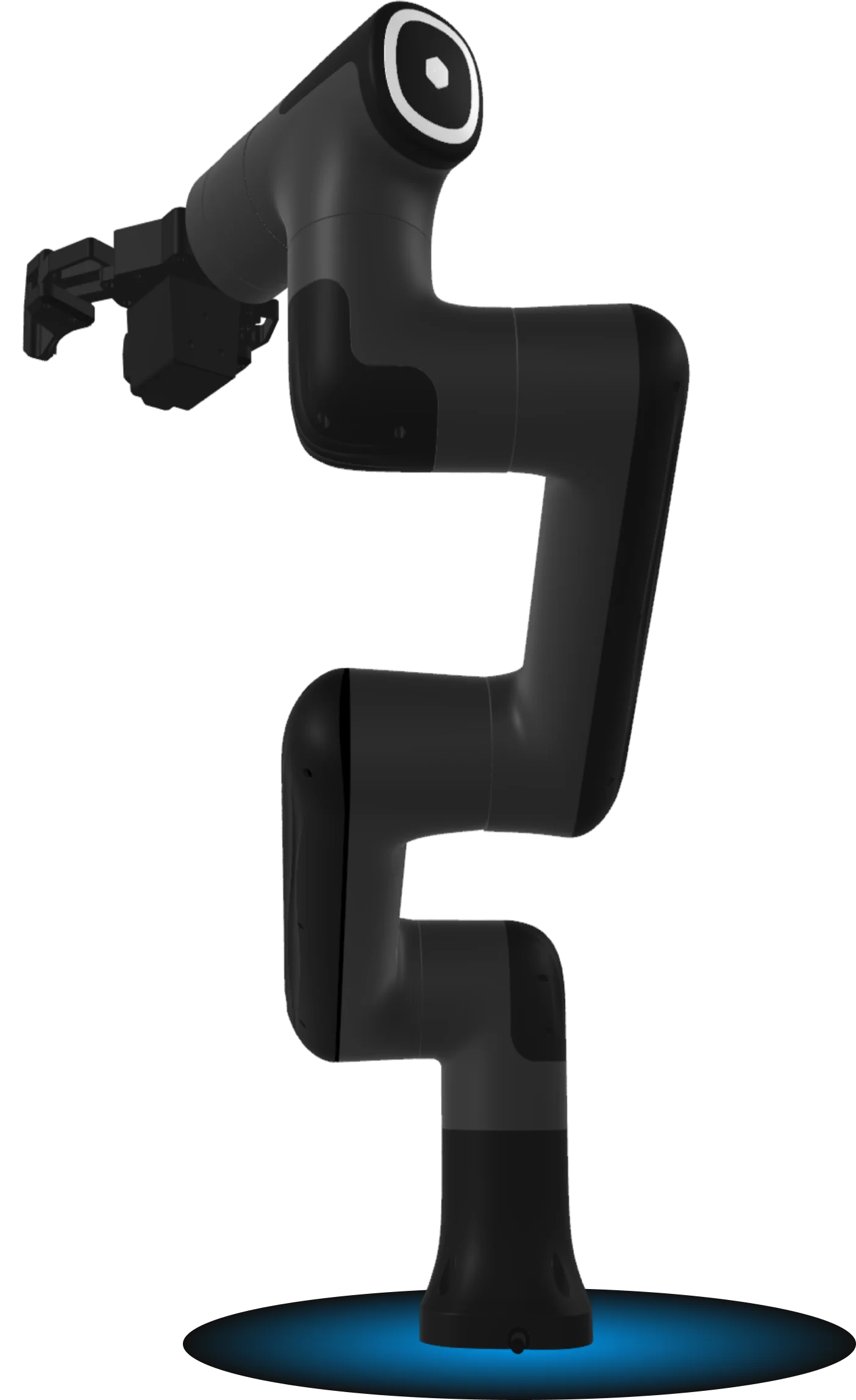

Industrial Robotic Arm Powering Precision Automation

Telos, the industrial robotic arm, excels in precision and efficiency, performing tasks with a repeatability accuracy of ±0.05 mm. Telos also offers customizable safety features, making it perfect for collaborative spaces.

In the fast-paced restaurant and hospitality sectors, Telos revolutionizes operations by improving turnaround times, supporting staff during busy periods, and ensuring consistent service quality. Its versatility extends to manufacturing and warehouse logistics as well, where it increases production efficiency and minimizes inventory management errors.

-

Automates repetitive tasks, ensuring efficiency and accuracy

-

Minimizes manual mistakes in repetitive critical tasks

-

Customizable aesthetics to align with different workspaces

-

Maintains production flow, and reduces operational downtimes

Customizable for your existing workflow

Telos: Robotic Arm Features

FAQs - Industrial Robotic Arm

Telos is engineered by one of the expert robotic arm manufacturers, focusing on precision and adaptability. Unlike other mechanical arms, Telos offers multifunctional capabilities with a user-friendly interface, making it ideal for a wide range of industrial applications.

Through its automated and precise operations, Telos reduces manual errors and speeds up production times. As an industrial robotic arm, it is designed to easily handle multiple tasks, increasing throughput and reducing downtime in any production line.

Yes, Telos excels in environments where precision is critical. With its superior robotic arm design, Telos achieves a precision of ±0.05 mm, making it perfect for tasks that require meticulous accuracy, such as in electronics manufacturing or laboratory research.

Telos offers extensive customization options to meet diverse industry requirements. This includes interchangeable tools, variable arm reach lengths, and customizable software interfaces designed by our robotic arm development company. These features allow Telos to be tailored to specific tasks and environments.

Absolutely! Telos is a versatile and highly customizable industrial robotic arm engineered to adapt to a variety of sectors with specific operational requirements. Here’s how Telos tailors its functionality across different industries:

Restaurant and Hospitality:

- Engages in food preparation, ensuring consistency and quality.

- Automates serving processes to enhance customer service speed.

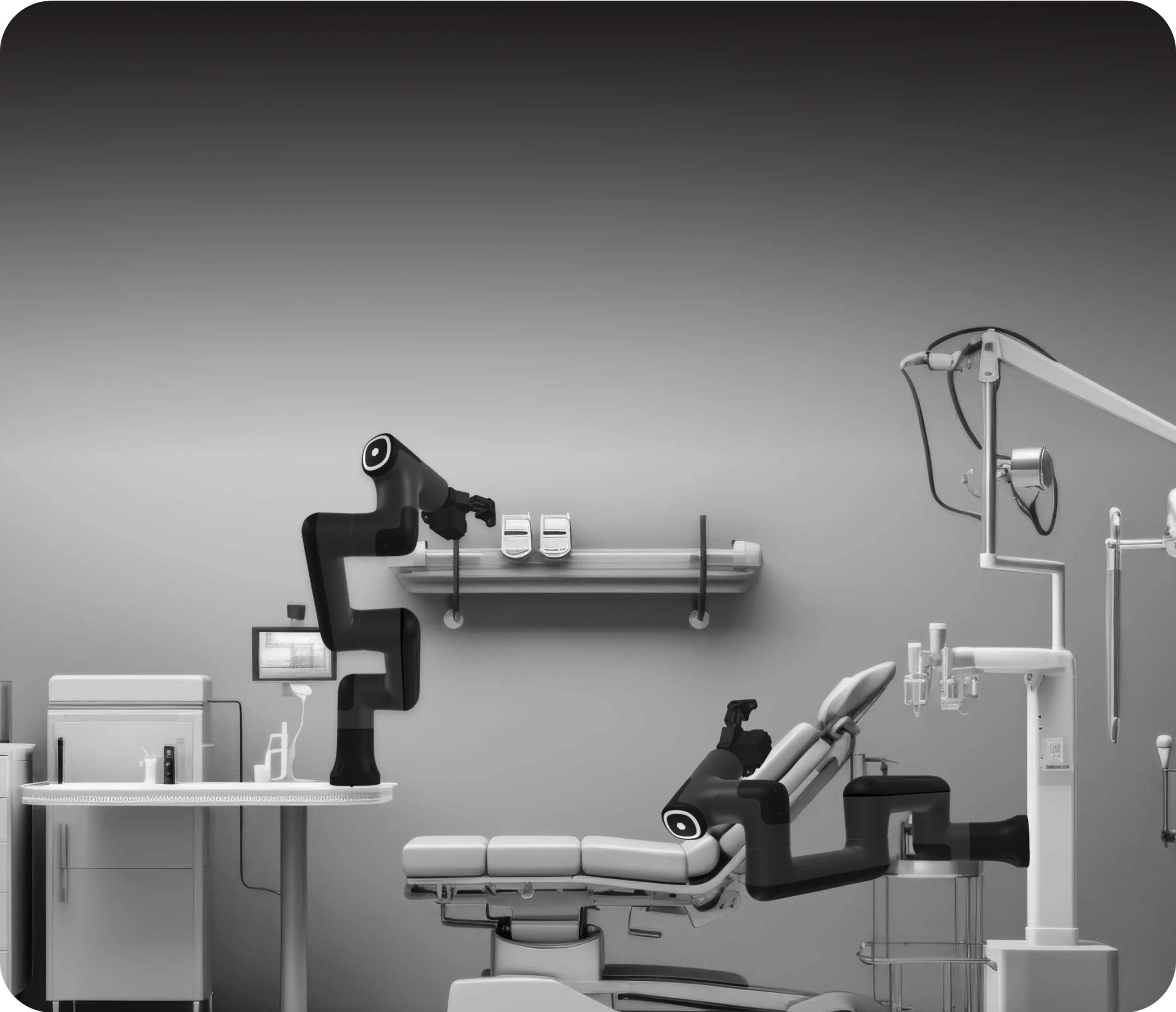

Healthcare and Laboratory Work:

- Assists in precise physiotherapy treatments.

- Minimizes human error in sample handling and testing.

Manufacturing and Assembly:

- Performs complex assembly tasks efficiently.

- Conducts quality assurance checks to maintain product standards.

- Manages material handling to streamline production lines.

Warehouse & Logistics:

- Automates loading and unloading tasks to increase throughput.

- Manages inventory with high accuracy to reduce discrepancies.

- Executes precise picking and packing tasks to improve order fulfillment.

Safety is paramount with Telos. This industrial robotic arm is equipped with advanced sensors and safety mechanisms to prevent accidents, making it ideal for environments where human-robot collaboration is frequent. The design complies with the latest safety standards, ensuring a secure operational setting for all users.

You can directly contact Kody Robots – robotic arm manufacturer, to order a Telos robotic arm. Our technical team streamlines and manages the installation process, ensuring that Telos is set up according to your specific needs and operational parameters.