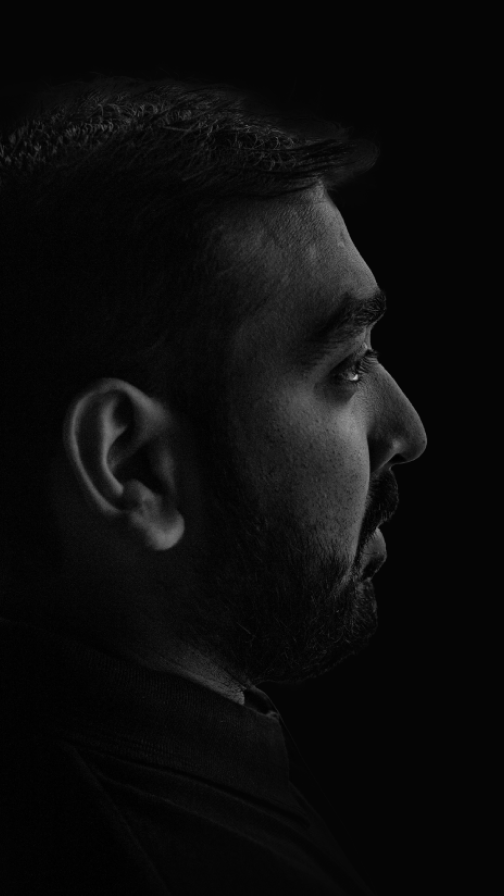

Mr. Manav Patel

Chairman and Managing Director of Kody Robots

Robotics is the natural progression of systems that demand precision and reliability. At Kody Robots, we design Autonomous Robots that understand space, interpret movement, and execute tasks with consistent accuracy. Our robots are built to operate in environments where performance cannot be compromised.

Our purpose is straightforward: engineer autonomy that strengthens operations and allows people to focus on work that moves businesses forward.

Robotics for Operational Excellence

Mission

To design and deliver intelligent robotics systems that transform how the world works; automating with precision, engaging with purpose, and elevating operational capabilities to empower industries to achieve more with less.

Vision

Empowering people, infrastructure, and industries with robotics solutions, AI, and intelligent software to shape a smarter, sustainable future.

Unlock the Full Potential of Your Operations with Robotics

Is Your Business Ready for Autonomous Performance?

Discover how our robots enhance efficiency, streamline workflows, and elevate performance across industries. As a leader in robotics manufacturing, we deliver intelligent automation that drives measurable business outcomes.

Testimonials

FAQs

We build robots that perform consistently in live operations. Every platform is engineered with three principles: predictable navigation, stable uptime, and long-term serviceability. Our approach as a robotics manufacturing company ensures that each robot delivers measurable improvements in environments where reliability directly impacts outcomes.

We use a stage-gate R&D model: research → prototyping → validation → stress testing → field simulation → manufacturing → controlled rollout. Nothing moves to production without quantitative performance benchmarks.

Each robot goes through precision calibration, multi-environment testing, hardware stress validation, and safety compliance checks. Our controlled manufacturing workflows ensure that every unit operates identically once deployed.

Each robot runs on a modular stack including perception, planning, mapping, fleet coordination, and safety layers; all developed in-house. This modularity allows for fast improvements without redesigning the entire system.

We use multi-sensor fusion combining LiDAR, depth cameras, IMU data, odometry, and AI-driven path prediction. Robots continuously update their understanding of surroundings to avoid obstacles and maintain optimal routes.

Robots automatically adjust to minor changes using real-time perception. For larger layout updates, our team performs quick remapping to ensure navigation accuracy remains consistent.

All robots receive over-the-air updates for navigation logic, perception improvements, UI enhancements, and system performance. This ensures that every deployed robot continues to evolve and perform better over time.

Robots undergo electrical isolation tests, controlled collision trials, speed regulation checks, and floor-condition testing before they are approved for live environments.

Our architecture prioritizes stability over complexity. Instead of relying solely on cloud processing, core navigation and perception decisions are made on-device, ensuring robot functions even with network instability.

We perform supervised live trials in partner locations, capture navigation logs, refine perception parameters, and revalidate until the robot demonstrates repeatable behavior under different crowd conditions.

We only ship features that improve operational efficiency or robustness. Input comes from customer feedback, route analytics, and internal testing, not trends or assumptions.

We provide operating manuals, safety guidelines, troubleshooting playbooks, mapping diagrams, system specifications, and workflow recommendations tailored to each site.

New models are released only when the use-case demand, engineering feasibility, and long-term serviceability align. We never release rushed or experimental units into commercial environments.

Indian robotics has matured significantly. With in-house R&D, domestic production control, faster upgrade cycles, and proximity-based support, companies like Kody Robots deliver more predictable and responsive automation than imported systems.

We use modular hardware for our robotics systems, standardized components, and consistent internal architecture, making repairs, upgrades, and maintenance fast and predictable.

Yes, customization is a key part of our service. We work closely with our clients to understand their operational challenges and tailor our robots' features, such as software algorithms, physical dimensions, and functionality, to meet those needs.

We provide comprehensive after-sales support, including installation, training, technical support, maintenance, and software updates to ensure our robots operate efficiently and continue to meet client needs.

You can contact our sales team via our website to make a purchase or learn more about our robots. We offer consultations to discuss your specific needs and the best solutions for your business.

Demonstrations can be arranged upon request through our sales department. We also participate in various trade shows that we update on our social media handles. So, make sure you follow us on Twitter, Instagram, Facebook, and LinkedIn.

We are committed to continuous research and development to push the boundaries of what robots can achieve. Our collaborations with tech leaders and academic institutions help us stay at the forefront of robotics innovation.